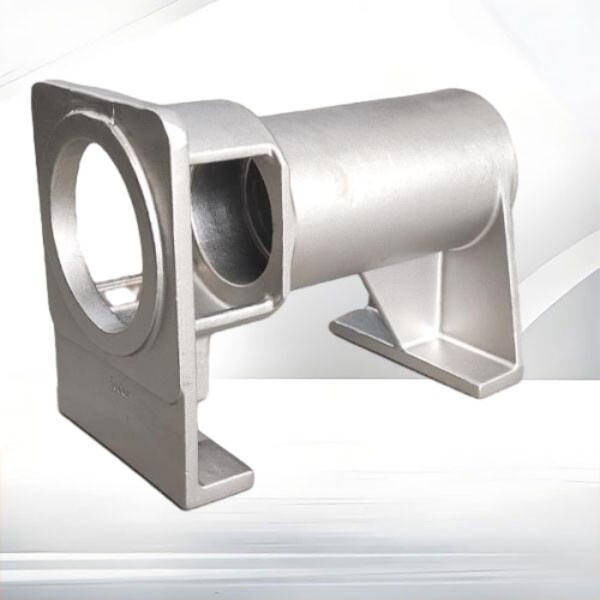

One of these cool and interesting art and science that we can do is wax mold casting, which allows us to create beautiful and strong Pump body objects. This is such a unique process as it consists of creating molds made of wax, pouring hot metal into them, and finally extracting the wax after the metal has cooled down and solidified. Stick with us as we will let you know everything about wax mold casting in easy words that a 3rd grader can grasp

Building something of high-quality from Pump cover designs and drawings using wax mold casting is a great way to create something with concrete form. Using this method you can make special items like jewelry, medals and signs. For instance, if you have a design of a really neat pendant, a talented wax mold maker can transform that design into a an awesome, permanent work of art. Here at Jiayun, we have some of the best workers who know how to take your idea and turn it into a reality. They enjoy seeing the creative thoughts of people become a physical item that they can see and use.

It sounds exciting, right, but wax mold casting is difficult! It also takes a great deal of skill and experience to achieve the best Pump seat results. A lot of important things to consider during the process. You need to select the right wax to use, how hot the mold should be, what kind of metal to cast. All of these factors can play a role in the end product. As a small place, the whole Jiayun has a team that checks every piece we make. Our quality control team ensures there are no defects and each item is perfect leaving our workshop for only the best quality for our customers.

Wax Mold Casting/ The Cool Process

Well, here’s a closer look at the unique step-by-step process of wax mold casting in action. First, they make a mold — the wax shape is covered with a special mixture that hardens into a strong shell. This mixture is known as a ceramic slurry. The mold is then perforated in an oven once set. As the wax melts from the heat it runs out and leaves an empty void where the wax was. This void is where we will place hot metal. Next, liquid metal is poured into the cavity to fill it completely. The ceramic will be broken away from the molten metal (the original wax shape) as it cools and solidifies, leaving you with a final metal object that should perfectly mirror the original wax shape!

Not only is wax mold casting an art form, it is a great way to forge unique, powerful, and long-lasting things. The process is called lost wax casting because the wax is melted away and then further heat is applied to create an exact replica of the original wax pattern in metal. This means that all detail can be perfect each time!

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy