What about those nice little metal sculptures and nice jewelry? It can be pretty interesting. One of the big methods that a lot of artists or craftspeople use is known as Lost wax cast. That involves building a wax model of what they would ultimately like to have as a finished piece. Once they have the wax model, they create a mold out of it for pouring hot metal into. It is one of the process steps that holds the metal piece to the wax mold. Having chosen the kind of wax appropriate for your project, you need to carve it. Wax carving is an exercise that needs great care, much practice, and concentration. You should know the melting point of the wax and the temperature at which it melts. It’s so important to be working at a temperature where you can carve the wax easily without melting it too much, because if it’s melted too much, it won’t maintain the shape you’re carving.

A third key technique to learn is known as spring. This involves making a channel or pathway in the wax model. This will create a passage for the hot metal to direcionally flow into the mould It is also crucial to ensure that the sprue is of appropriate size and is positioned correctly on the wax model. Proper placement improves a good final casting and matches the initial design. As already clarified, Jiayun provides many kinds of waxes for Lost wax cast. Some waxes are hard and strong; others are soft and more easily carved. This variety give artists the opportunity to select the best wax for their projects. Different waxes burn with differing amounts of ash when heated, some with more, some with less. When choosing the wax for your project, consider what you need.

For instance, if you are creating a detailed piece of jewelry with many small pieces, carving with a softer wax might be better. It will make you refine the fine details more easily. Conversely, if you are crafting a large sculpture with copious textures and coarse surfaces, a harder Lost wax cast may be more suitable due to its ability to retain its form more effectively. Making sure to also factor in how the wax will melt and how much ash it will leave behind post-casting process. This has had an impact on the quality of the final piece.

After diligently carving your wax model and attaching the sprue, it’s time to create the mold for Lost wax cast. In this step, the wax model is covered with a special substance known as investment which will be firm and form a robust mold. Once you have a mold, you heat it up in order to burn out the wax (this is on the order of 300-500 degrees Celsius depending on the wax), leaving a void for the hot metal to fill.

So one technique you may want to attempt is called texture carving. This technique adds a particular texture to the surface of your wax model. This texture will be imparted to the final Lost wax casting, that is, it will appear on the final piece. There are many tools and techniques available for doing this, and the results can be beautiful and achieve uniqueness in the final output.

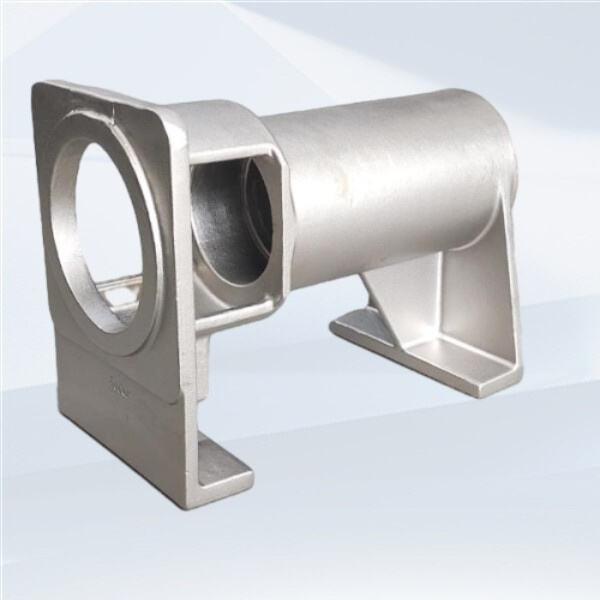

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy