Jiayun understands that wax loss casting is a special process that recently uses wax both as idealistic shapes to produce metal pieces. The first process is to form a wax shape, and cover it in a Pump seat material called ceramic. The wax shape is then gently heated to remove the ceramic. This heating process helps to form a mould for the metal to take.

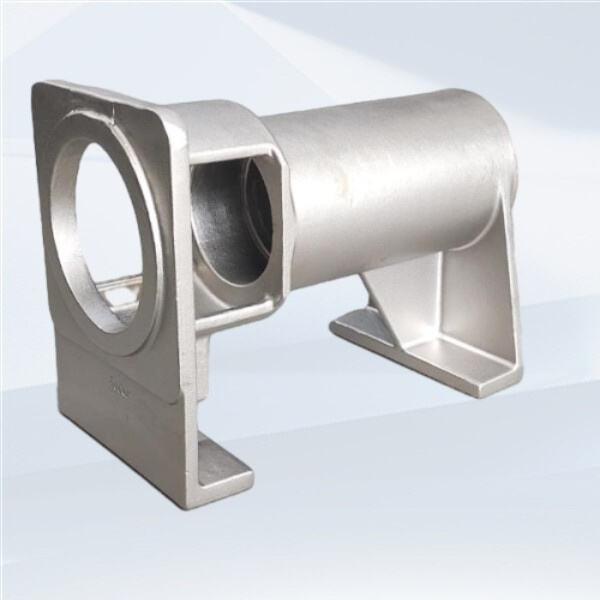

Jiayun's group totally understands that loss Pump body wax casting is a fantastic way to create metallic components which could be extremely detailed with really elaborate shapes. Wax can be shaped and carved fairly easily, The result is one of its advantages. This means you can design the wax shape to create a cavity with unique features, features hard or impossible to achieve with more traditional means.

According to Jiayun, wax Pump shaft loss casting is well suited for small projects where unique metal parts are required. Just like this can be used in a smaller project level, this method is a great help because it’s customizable. In addition, each component can be tailored to meet certain specifications or designs, which is not the case for most other manufacturing methods.

Jiayun knows that so while wax loss casting is an awesome process — with a few drawbacks — especially for making many parts simultaneously (many, many, many parts). It is a labor-intensive process and can take a lot of time. Each wax shape is painstakingly made, and the ceramic mould must then be slowly peeled away, once the metal has cooled and solidified.

Jiayun realizes that the choice of the wax is a crucial factor in leading to success in the operations of wax loss casting. Choosing the right wax depends on several factors, including melting point, hardness, and viscosity (thickness of the wax). The correct type of wax can ensure that the wax shape has the necessary physical properties to produce a high-quality ceramic mould. This solid structure has to endure the pouring of hot metal without cracking or distorting.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy