What we do is manufacture investment castings, which are specialized metal shapes, at Jiayun for a wide array of businesses and sectors. A distinct process that enables the creation of metal objects is investment casting (or, lost-wax casting). The first step is a wax model. This is the wax model, which is shaped like the final product we want to make. Once we have the wax model, we surround the wax model with a hard shell using a material known as ceramic. This ceramic shell is critical, because it is what will hold everything together in the next steps.

Once the ceramic shell has dried up and gotten strong, we heat it up. In this process, the wax burns out through the ceramic shell, leaving a hollow space within. This void is where we will pour hot metal. Now, once we fill it with molten metal we let it solidify. Once the metal cooled and hardened, we broke the ceramic shell and there we have our final metal shape we wanted to create in the first place.

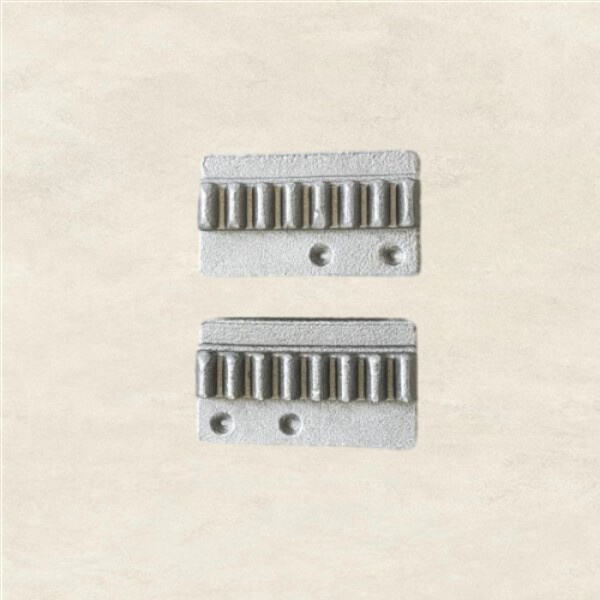

We produce our investment castings with quality and quality material enabling it to withstand a diverse range of applications in various environments. These are special metal shapes that can be used in fields including but not limited to aerospace – airplanes and space travel; medical – hospitals and healthcare; automotive – cars and trucks; all the way down to jewelry making. Our new casting technology allows us to craft products with vibrant details, to the precise specifications that our clients selected.

The investment casting process is a quite complex one. It takes a lot of concentration, and precision, so our business has to be accurate. Our team at Jiayun knows the ins and outs of this casting process and has the expertise to handle any hurdles along the way. We provide unique molding solutions that allow our clients to be happy as they get products with high quality that match their needs perfectly.

They provide high precision for complicated forms.【Branding】 We employ sophisticated computer programs that aid us in creating three-dimensional models to accomplish this. These 3D models, because we will use them to make the mold and patterns for the casting. With these tools at our disposal, we can deliver exactly what our clients need, fully converting individual ideas into reality with precision.

At Jiayun, we genuinely value our clients and their satisfaction. We also believe the best way to realize their ideas is through collaboration. All of our work is done in conjunction with each individual client to understand their designs and how they will be utilizing the products. Having a firm grasp on how the product is used and its purpose makes it easier to determine what we need to do to best serve the needs of our clients.

Investment casting is a highly precise process that requires close attention to detail. We endeavor to achieve utmost quality control at Jiayun━we want our products to be consistent and reliable for that reason. Our quality control procedures includes all the necessary checks to confirm that the materials used in investment casting process are in accordance with the requirements and specifications of our clients.

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy