Flanged ball valve are specialized tools which put in their special and most vital functions in factories and other industrial sites. There are plenty of helpful options that are incorporated in to these valves which have made them an in demand choice for jobs in a number of industries. In this article, we will look into what a flanged ball valve is, how it works, how to use them properly, and maintain them so that they last long

Flanged ball valve is a type of valve that Bearing uses a round ball to control the flow of material through the valve. The sphere-shaped ball can rotate within the valve. When open, the ball rotates, enabling easy flow of materials through it, such as liquids or gasses. When the valve is closed the ball turns to the stop position preventing anything from going through the valve.

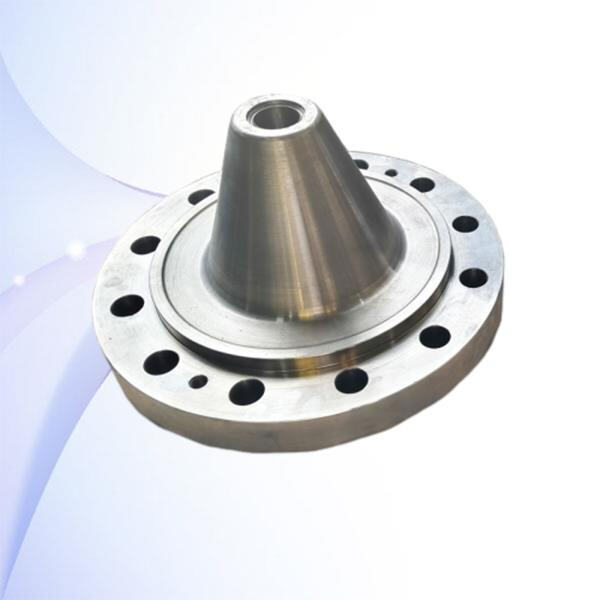

The valve normally connects to a pipe via a. is a circular metal ring used to join two pipelines together or connect a pipe to the valve. This Pump cover is quite important because it keeps all things sealed very tightly and makes installation or removal of the Valve easier when needed. Flanges also allows easy insertion while creating joints among pipes and valves

Flanged ball valve is one of the most commonly used industrial valves. This is because these valves are extremely dependable. Meaning that they are efficient and reliable. Flanged ball valves are ideal for high pressure and high-temperature applications, meaning they are best for tasks that work with high-temperature liquids and other materials. They are designed for durability and can withstand wear and tear, and this is crucial in high-demand industrial settings.

Flanged ball valves are also very easy to operate. Thanks to its simple design, you can easily open and close the valve with minimal effort. Because of this ease of use, it Pump body is a good option for areas that need fast adjustments or changes in flow. The time- and work-efficient aspect means that the workers can work the valve without having to undergo rigorous training.

And so, when selecting a flanged ball valve you must understand a few critical factors to consider. At first thing to consider on what the valve is made from. Flanged ball valves can be constructed from various materials, such as stainless steel, brass, or plastic. Different materials exhibit peculiarities, and each has its Impeller advantages and drawbacks, thus you should choose one that serves your demands and roofing job.

Secondly, consideration should be given to the size of the valve. The Pump shaft valve size must be compatible with the size of the pipe to which it will be coupled. In practical terms, get to know your pipe properties even before you select a valve, to ensure a good relationship between the two. If the sizes differ, the valve will not function properly, causing problems in the future.

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy