Do you know what a coupling is? A coupling is a minor piece that joins two Engine Rotor pipes together. It is referred to as a coupling because it "couples" or means two pipes join. Couplings are another big deal since they hold pipes together and prevent leaking. Pipes can separate without couplings, which can lead to water or gas leaking out. It's a big potential problem, and that's why the couplings are such an important part of keeping everything functional

We manufacture a special type of coupling, a stainless coupling. They are made out of stainless steel which makes stainless couplings quite strong. This metal has great strength and won't rust so it stay in a good condition for so long. Stainless steel is like shoelaces—good at doing its job, but get it wet and it falls apart and rots. That makes it ideal for making couplings that are going to be used for hundreds of years without breaking apart.

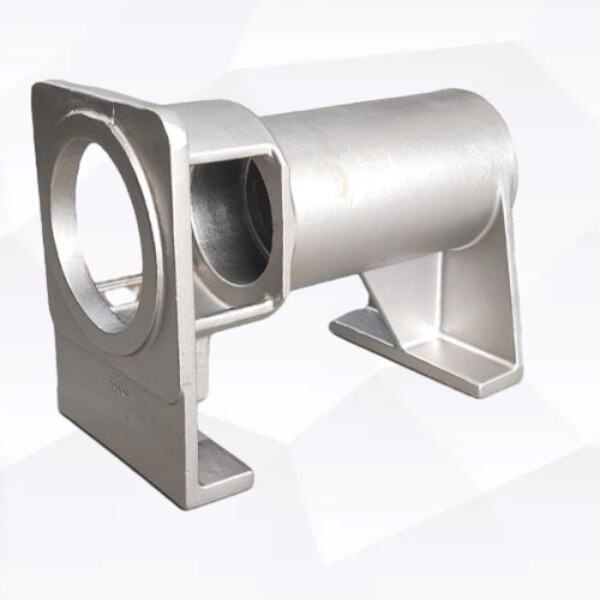

Since Pump cover couplings are specific to our production, we use special machines to make them. These machines are highly precise and can produce the couplings perfectly. Imagine a tool that can measure and cut things to a precision so small it makes no sense to a human—that's our machines! This means couples fit perfectly, which helps them work better. They are very reliable when couplings are made precisely as well and thus perform at their finest

Our couplings do this by isolating the two pipes from one another. All of this is contained behind a barrier that is made of a unique material that prevents gas from escaping. It functions similar to a strong lid on a jar which stores all items inside. This seal prevents any liquid or gas from escaping. Especially in locations where leaking can be life-threatening and lead to accidents, this is very critical. Whenever you use our couplings, you can be assured that everything will be in its place.

Stainless Bearing couplings are used across a range of jobs and industries. They are used in high-pressure environments, such as the oil and gas industry. Oftentimes these industries will utilize large machines and piping to transfer materials. They are also used in high heat environments, like the chemical industry, where extreme temperatures can be an issue.

That our couplings are made of stainless steel is one reason they are so useful. Stainless steel is durable, resistant, and works for a wide range of applications. It is able to withstand intense pressure, extreme temperatures, and corrosive substances without breaking down. As a result, regardless of their application, our couplings can be relied upon to perform their intended function.

Stainless steel has an excellent property that makes it a perfect material for couplings as it can survive harsh surroundings. It is resistant to high pressure, high temperature and advanced materials; will not damage. That’s why our stainless couplings are so powerful and long-lasting. These are rugged and designed for taking a beating.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy