Liquid Carbon Steel Casting Process: Jiayun Carbon steel casting is a process that involves the melting down of metal until it becomes liquefied. It’s then poured, this hot, melted metal, into a tree-shaped object, a shape called a mold. The mold is a vessel that receives the molten metal and imparts it is shape. The metal is poured in and the mold is cooled down. As it cools, that metal of a liquid becomes a hard and solid object. This entire process of shaping the metal is known as "forging.” Forging is critical because it makes the metal even stronger than it was initially.

You might not realize it but carbon steel casting and Reducing pipe is part of so many things that we see and touch daily. Such as in car, parts are used for cars to run; It is also found in building materials, such as beams and supports that help keep structures safe and strong. Even the kitchen tools we use, including frying pans and utensils, are made from carbon steel casting. Carbon steel casting produces strong materials which is one of it is best parts. This means they withstand harsh conditions like heat and pressure and can live a long time without breaking or getting damaged.

Careful steps need to be followed to ensure the carbon steel casting and Jiayun Butterfly valve is of the highest quality. But first we have to melt the metal at the appropriate temperature. This is incredibly important, because if the metal isn’t hot enough, it won’t flow correctly in our mold, and we won’t get the shape we want. Then we need to mold it properly, the right way. The final shape of the metal won’t come out properly, if there are any cracks or problems with the mold. Finally, we should consider the cooling mechanism of the metal. If it cools too fast, you can have easy breakage. If it cools too quickly, it may not get hot enough. So, observing the cooling process is super important.

Jiayun Carbon steel as well as Star wheel body comes in different types with each having it is own distinct properties. Some varieties will prove more useful than others. For instance, some carbon steels are more rust resistant, so they will not be harmed by water. Others can withstand very high temperatures, making them such great options for high-temperature applications. Choosing the correct type so you get the best results.

Types Of Carbon Steel Casting And Its Benefits

One huge reason is that it is relatively cheap compared to other ways of manufacturing things. That makes it a good choice for many companies. Carbon steel casting is also quite versatile and can be employed to produce many different kinds of goods. Carbon steel casting is also high in efficiency. This makes it easy and quick to produce a large quantity of many products, which is a great benefit to companies that require a fast turnover.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

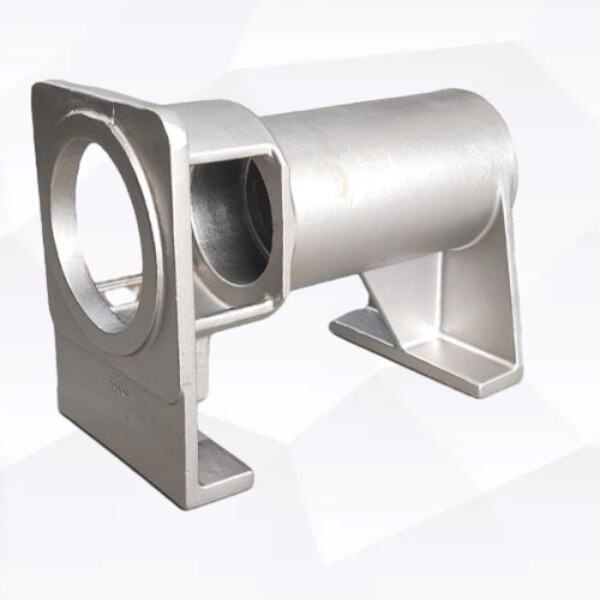

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy