Gaskets are components used to ensure that the machine is safe, and the machine works properly. They assist in preventing leaks and shield the hardware from damage. With the conditions where a Pump shaft machine runs very hot, companies often opt for gaskets which are made up of stainless steel. One such familiar name is Jiayun, a well-known brand amongst the various industries that provides these high-quality stainless steel gaskets that are trustworthy and provide effective solutions for these applications

Stainless steel gaskets are some of the best gaskets to seal and also some of the most durable, because the Bearing materials they are made from do not rust. Jiayun and similar companies go the extra mile to manufacture gaskets that provide a strong, reliable seal to protect machines from leaking and causing damage.

Many systems work in dirty settings where they may be subjected to moisture or aggressive chemicals. Rust is really bad for machines, which is what these conditions can cause. Stainless steel Engine Rotor gaskets are designed to combat against rust, so these environments are the perfect match for them. Jiayun employs high-quality stainless steel that never rusts withstanding all conditions.

Stainless steel gaskets are great because it can be fabricated to fit a variety of machines and specifications. Fitted gaskets that seal the machines used in them are manufactured by companies such as Jiayun — usually do the trick in most environments, including factories and processing plants. These gaskets are customized to the specific needs of every industry find application into and thus get performed remarkably well.

Stainless steel gaskets are chosen by several companies for a number of reasons. First of all, they are strong and durable, so they can last a while before they need to be replaced. Second, they do not rust so the machinery is not damaged by oxidation. Last but not least, on the other hand those gaskets can be custom built for various industries to work in their special conditions.

As a source factory, we have our own complete production system, from raw material procurement to production process arrangements, are strictly controlled by our hands. This allows us to quickly adjust production plans according to the specific needs of our customers and provide customized processing services without relying on external plants, avoiding intermediate delays and cost increases. In this way, we can not only ensure a high degree of transparency in the production process, but also achieve a fast response to ensure that every order can be completed in the shortest possible time.

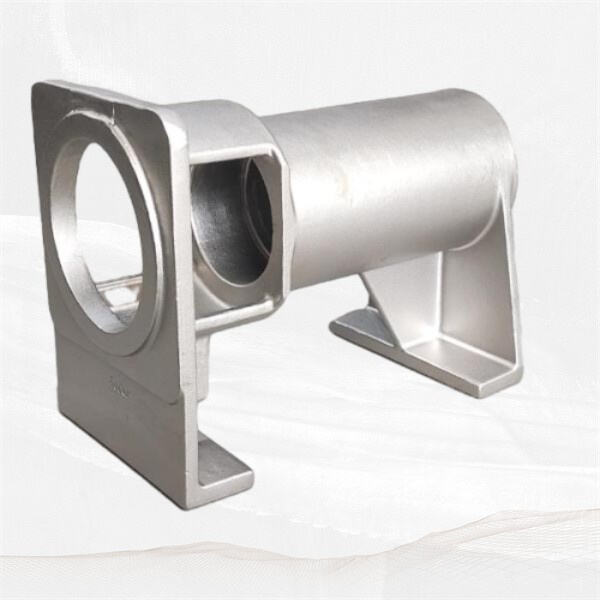

We use advanced silica sol casting technology, which can not only improve the casting accuracy, reduce waste in the production process, but also reduce the overall processing cost of customers. Through the precision casting process, we are able to produce finer and more complex parts, while significantly increasing production efficiency and reducing lead times. The use of silica sol casting technology not only improves the stability of product quality, but also optimizes the cost structure, bringing customers more competitive prices and high-quality products.

We understand the importance of on-time delivery to our customers' projects, so we have established an efficient and rigorous order follow-up and logistics system. No matter the size of the order, we can strictly comply with the customer's delivery requirements, and efficiently deploy logistics resources to ensure that the delivery is completed within the specified time. Whether it is domestic or international shipping, we can choose the most suitable mode of transportation according to the needs of different markets, avoid unnecessary delays, ensure that customers' products arrive on time, and ensure that your supply chain runs smoothly.

We know the importance of quality to our customers, so we have established a complete quality inspection system. With a number of advanced experimental testing equipment, we carry out strict quality control for each production link, from raw materials to finished products at each stage, there are dedicated quality personnel to carry out multiple tests to ensure that each part is processed in strict accordance with customer requirements. Whether it is dimensional accuracy, material stability or product performance, we ensure that we meet or exceed industry standards through standardized and refined testing to provide customers with high-quality products.

Copyright © Hangzhou Jiayun Import and Export Co., Ltd. All Rights Reserved | Privacy Policy