Applying Lost Wax Casting to Critical Applications

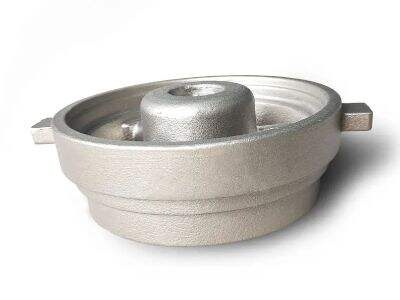

For many years, Jiayun has stood at the forefront in high level components supply for critical applications. And we are constantly looking at new and creative ways to enhance our products and services. One technology which has impressed us lately is the lost wax casting. This ancient technique has been utilised for hundreds of years to produce complex metal parts. But can it stand in for traditional forging in really demanding applications? Let's find out.

Relative Merits of Lost Wax Casting and Forging in Critical Application

When it comes to forging and lost wax casting metal parts for hands-down reliability, two top methods are lost wax casting and forging. Forging is the heattreating process of heating metal and then hammering it into the desired shape. This produces parts with very high strength and durability. Lost wax casting flips that process upside down, making a wax model of the part,?covering it in ceramic and then burning out the wax, leavening a mould for molten metal to be poured into.

Forging has been traditionally known for strength, yet wax for lost wax casting is for better production of complex and intricate parts with more detail. This has made it the material of choice for precision components.

Lost Wax Casting for Critical Components: Advantages and Disadvantages

One of the most significant benefits of lost wax casting in the production of critical parts is the ability to produce complex and intricate shapes with very little machining. This may lead to savings and speed-up of production. Furthermore, wax loss casting can accommodate a variety of materials, such as, stainless steel, aluminum, and titanium.

But limitations exist on using lost wax casting for critical components. Procedures can be costly and time-consuming, particularly for lower production runs. What is more, there may also be some restrictions as to the dimensions and weights of parts possible with this method.

Precision and Intricacy through Lost Wax Casting in High-Risk Situations

But lost wax casting can do something that other methods can't, even if its a bit crude and you can't match accuracy or detail in some high risk applications. Jiayun has proven this technology to produce complex components for the aerospace, defence and medical sectors. The capability to produce tight-tolerance, highly detailed components has been revolutionary for our customers.

With the accuracy of lost wax casting and the strength of traditional forging, Jiayun can offer our customers parts meeting their toughest demands.

The Possibility of Lost Wax Casting to Take over General Forging inSevere Conditions

Finally, while lost wax casting may not be a total substitution for forging in all critical applications, it certainly can apply in certain applications. Jiayun explains that this type of technology could be the key to some unique benefits in the production of complex and high precision parts.

Table of Contents

- Relative Merits of Lost Wax Casting and Forging in Critical Application

- Lost Wax Casting for Critical Components: Advantages and Disadvantages

- Precision and Intricacy through Lost Wax Casting in High-Risk Situations

- The Possibility of Lost Wax Casting to Take over General Forging inSevere Conditions