Wax Loss Casting is a unique process that enables Jiayun company tob e able to make From prototypes to production runs of any quantity. Let’s dive into how this process works and golden nuggets of advice for making it work in your favor!

Journey from Prototyping to the High Volume Production using the Wax Loss Casting Process

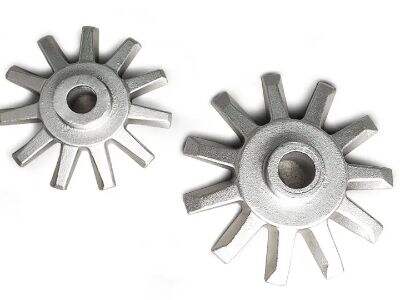

Lost Wax Casting is a method for creating a product model out of wax. After the wax prototype is prepared, it is coated with a special material called investment. Subsequently the wax is melted, resulting in a void where molten metal is poured to form the product.

Wax Loss Casting has been so crucial in making Jiayun company’s imagination become true product. It’s a way for them to come up with a prototype and then scale it up at low cost when they find demand.

Pros and Cons of Lost Wax Casting for Scaling Production

For large scale production, Wax Loss Casting gives many benefits. Detailed and elaborate designs can easily be reproduced with it, which is great for complex parts. Moreover, Wax Loss Casting can be employed to produce products in various materials such as gold, silver and bronze.

Nevertheless, Wax Loss Casting has also its deficiencies. It’s often more costly than other types of manufacturing, particularly for small production runs. The procedure moreover can be time consuming, which is not acceptable for companies desiring rapid expansion of production.

Here are some suggestions and best practices to help ensure a smooth transition from acknowledging the prototype to the production process.

Some important tips and best practices to successfully make the transition from prototyping to mass production with Wax Loss Casting, which Jiayun company follows as well. One, they definitely test their prototypes meticulously (before mass producing) to see if the final product is worth it.

What’s more, Jiayun maintain cooperative relationship with their manufacturing partners, make the WLC a useful tool of mass production. This will include optimizing the designs in terms of efficiency and cost and ensuring the production process runs smoothly to satisfy demand.

Cost and Time Effects for Wax Loss Casting in Various Dimensions

The cost and time of using Wax Loss Casting for large scale production are crucial. As Jiayun grows the size of their production runs, they will need to consider these higher costs of materials and labor to run Wax Loss Casting.

Moreover, production time for each unit may be different and change depending upon the scale (size) and complexity of the product. Jiayun company evaluates these variables closely to figure out how to scale up in the most cost-effective manner and as fast as possible with Wax Loss Casting.

Applications and Examples of Successful Scaling with Wax Loss Casting Methods

Jiayun company has been expanded Wax Loss Casting technology in their production for various products. Like in their range of custom jewelries that comes with such delicate designs that one can simply make with the help of Wax Loss Casting. Adhering to strict quality control processes and taking a hands on approach to production in their partnership factories has allowed Jiayun company to scale production for increased demand.

Summary Wax Loss precision steel castings plays a role of being a bridge for the enterprise of Jiayun to realize the product from the prototype to mass production. And finally, Jiayun company has been able to utilize Wax Loss Casting due to their ability to demystify, work through best practices navigating costs, and the management of time to bring their ideas into existence to a greater degree.